Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse

Prev

Next

Next

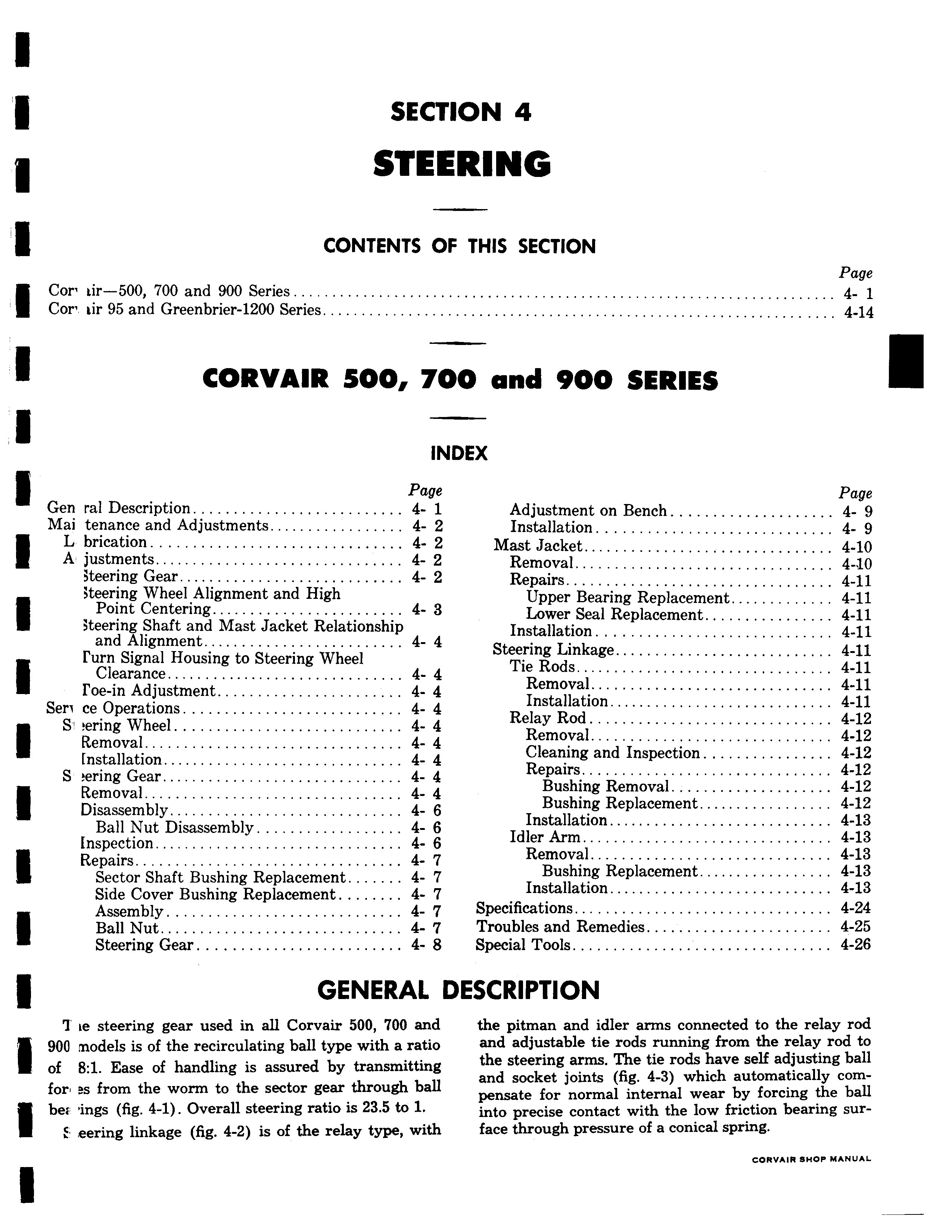

SECTI STEE CONTENTS OF I Cor tir 500 700 and 900 Series Cor vir 95 and Greenbrier 1200 Series CORVAIR 500 70 INI Page Gen ral Description 4 1 Mai tenance and Adjustments 4 2 L brication 4 2 A justments 4 2 3teering Gear 4 2 teering Wheel Alignment and High Point Centering 4 3 3teering Shaft and Mast Jacket Relationship and Alignment 4 4 Curn Signal Housing to Steering Wheel Clearance 4 4 Toe in Adjustment 4 4 Seri ce Operations 4 4 S ering Wheel 4 4 Removal 4 4 fnstallation 4 4 S ering Gear 4 4 Removal 4 4 Disassembly 4 6 Ball Nut Disassembly 4 6 Inspection 4 6 Repairs 4 7 Sector Shaft Bushing Replacement 4 7 Side Cover Bushing Replacement 4 7 Assembly 4 7 Ball Nut 4 7 Steering Gear 4 8 GENERAL C 7 ke steering gear used in all Corvair 500 700 and 900 models is of the recirculating ball type with a ratio of 8 1 Ease of handling is assured by transmitting for es from the worm to the sector gear through ball be ings fig 4 1 Overall steering ratio is 23 5 to 1 eering linkage fig 4 2 is of the relay type with ION 4 RING THIS SECTION Page 4 1 4 14 10 and 900 SERIES EX Page Adjustment on Bench 4 9 Installation 4 9 Mast Jacket 4 10 Removal 4 10 Repairs 4 11 Upper Bearing Replacement 4 11 Lower Seal Replacement 4 11 Installation 4 11 Steering Linkage 4 11 Tie Rods 4 11 Removal 4 11 Installation 4 11 Relay Rod 4 12 Removal 4 12 Cleaning and Inspection 4 12 Repairs 4 12 Bushing Removal 4 12 Bushing Replacement 4 12 Installation 4 13 Idler Arm 4 13 Removal 4 13 Bushing Replacement 4 13 Installation 4 13 Specifications 4 24 Troubles and Remedies 4 25 Special Tools 4 26 IESCRIPTION the pitman and idler arms connected to the relay rod and adjustable tie rods running from the relay rod to the steering arms The tie rods have self adjusting ball and socket joints fig 4 3 which automatically compensate for normal internal wear by forcing the ball into precise contact with the low friction bearing surface through pressure of a conical spring aORVAiR SHOP MANUAL

Next

Next